Symbols can be copied from the schematic editor into a schematic library, copied between schematic libraries, or created from scratch using the Schematic Symbol Generation Tool or drawing tools. This document outlines the creation and management of schematic libraries ( *.SchLib). To learn more about creating a component symbol itself, refer to the Creating a Schematic Symbol page. Placed directly from a connected Workspace, accessible for the entire design team.Created in and placed from local libraries or.The real-world component that gets mounted on the board is represented as a schematic symbol during design capture, and as a PCB footprint for board design. Parent page: Working with File-based Component Libraries Moving a Design from One Location to Another.

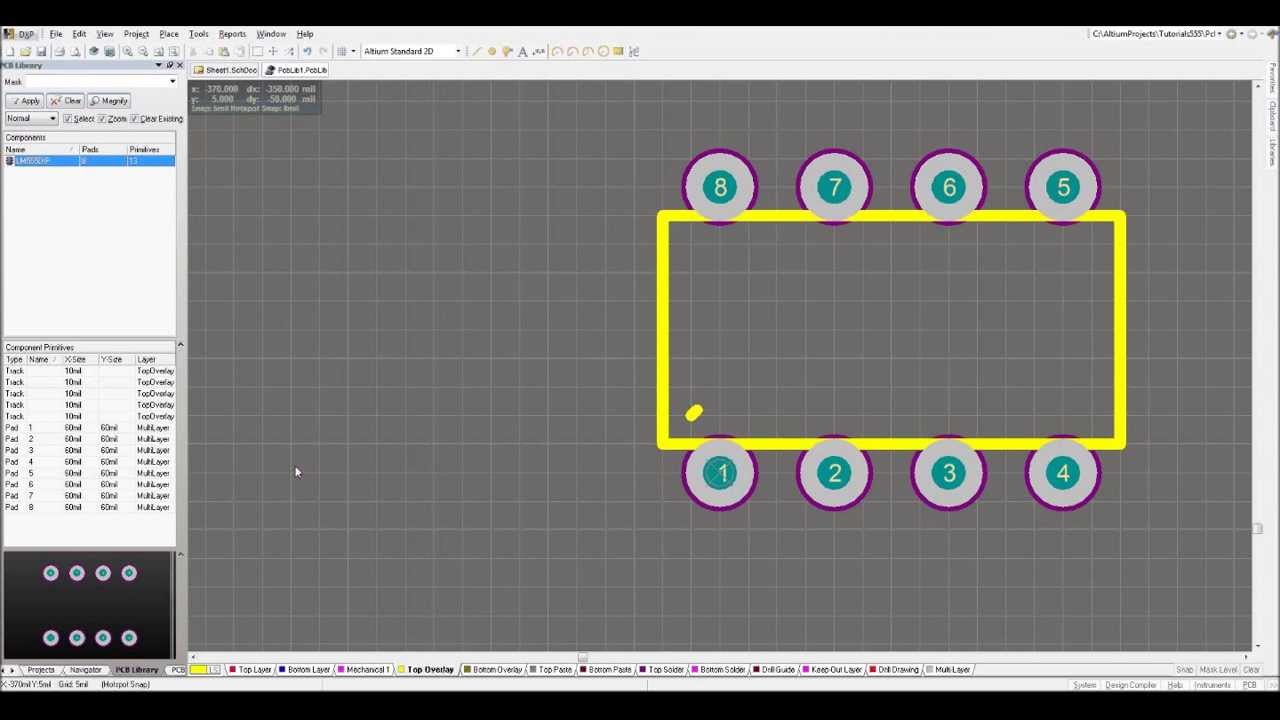

Moving and Copying Components from Other Libraries.Checking the Component and Generating Reports.Defining Clickable Links to Reference Information.Mapping a Parameter into the Component's Comment Field.Adding Parameters to Multiple Components.Using Parameters to Add Detail to the Component.Adding a Simulation Model to the Schematic Component.Adding a Footprint to the Schematic Component.Adding Models to the Schematic Component.Creating a Schematic Library from a Schematic Sheet.Creating a Schematic Library from Schematic Documents.This connector cannot be created automatically using the IPC Compliant Footprint Wizard, so it must be created manually using the recommended PCB layout view from the datasheet. If you have closed the tab with this component, search for it in the Components panel, right-click on its name then select Edit. Let’s create a footprint for the GSB343K33HR component whose symbol was created in chapter 5.1. In Altium Designer, the process of creating footprints is simple, convenient and protected from errors as much as possible. Any error in the placement of the footprint pads can lead to problems, up to and including the inability to assemble the final device, so library designers should be very careful while creating footprints. Also, the component itself will be soldered onto these contact points, so their configuration should be fully consistent with the actual metal objects of the component. Component footprints contain a set of graphical primitives and copper pads or holes that will be connected to the conductors and will provide a connection. The next step in creating the component is to design the footprint.

0 kommentar(er)

0 kommentar(er)